Wax dipping

Exceptions to destruction by burning

The brood, bees and honey from an AFB hive must be destroyed by burning. However, supers, lids, floorboards, queen excluders and feeders can be sterilised with permission from the Management Agency.

How to sterilise

Non-plastic hive parts can be sterilised by dipping them in paraffin wax at 160°C for at least 10 minutes. Both the time and temperature are crucial, so it is essential that a timer and thermometer are used. Temperatures less than 160°C or dipping times less than 10 minutes will not kill all the AFB spores. The thermometer must be strongly made (e.g. commercial food manufacturing grade), and should be capable of reading temperatures up to 200°C.

Non-plastic parts must be sterilised by dipping in paraffin wax at 160°C for 10 minutes.

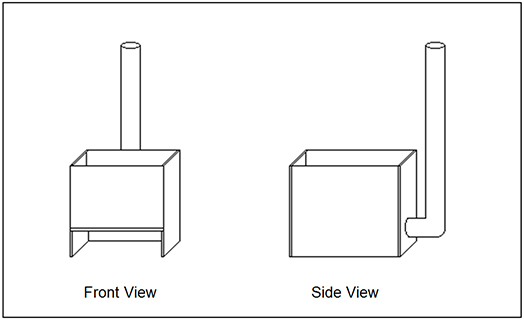

Wax dipper designs

There are a number of designs for wax dippers (Fig 59 and 60). The device is made of welded 5mm plate steel, and has dimensions of 600mm long by 500mm wide by 600mm deep, with an extra 125mm on three sides to make a fire box that can be fuelled from the front with waste wood. There is also a two metre high chimney to provide good draft. Alternatively the wax dipper can be heated with gas or electricity. This dipper has a capacity of two full depth supers turned on their sides, with a third super slipped over the other two.

Use Parafin wax

Paraffin wax in commercial quantities is available from oil companies. The recommended grade for wax dippers has a melting point of approximately 60°C. The wax dipper shown above will require about 130kg of wax. To avoid boil-overs, the wax level in the dipper, when melted, should be no higher than 125mm below the rim. The fire may need to burn for 1.5 to two hours to bring the dipper up to the required temperature of 160°C.

Use with caution

Care must be taken when handling paraffin wax at high temperatures. There is the obvious risk of burns, so protective clothing needs to be worn. Heavy-duty industrial rubber gloves are recommended, and eye protection should be used. A set of long-handled tongs is an essential piece of equipment to remove the dipped woodenware from the hot paraffin.

Paraffin wax has a flash point of 182°C, so the temperature must be kept well below this level, especially since the use of an open fire often results in wide fluctuations in temperature. Water sprinkled directly into the fire box can be used to quickly reduce the temperature. Some wax dippers can also be heated by gas or electricity (Fig. 61). Although these are more expensive to operate, they are safer and provide better temperature control.

How to operate the wax dipper

The dipper should be covered when not being used, and the woodenware to be dipped should be as dry as possible, since excess water can cause the wax to boil over the side of the dipper and ignite when it comes into contact with the fire box. For this reason it is good to build a wax dipper with an overflow that takes surplus wax away from the fire (Fig. 60).

Water should never be used directly on a paraffin fire, since it will cause an explosion. A cover should be made out of plywood or galvanised metal that fits securely over the top of the dipper. This should be kept nearby and used to suffocate any paraffin fire that might develop. Dampened sacking can also be used for this purpose, provided that the sacking is not dripping wet.

Never apply water directly onto a paraffin fire or allow paraffin wax to get wet as it will boil.

Care needs to be taken in siting wax dippers. One beekeeper had his dipper several metres from a tin shed where he kept supers. The wax boiled over, caught fire, and then ran under the wall of the shed. A lot more supers were sterilised than he had intended.

Take the AFB 5 minute quiz

How well do you know what you need to know about AFB and beekeeping? Take our short quiz and find out.

Videos

Our videos cover everything from your legal obligations to how to recognise AFB, collecting cell and bee samples and more.

Symptoms

There’s a lot of good information here, telling you everything you need to know about recognising AFB: the visual symptoms, smell of AFB and more.

Inspection and Diagnosis

Successfully eliminate AFB by telling the difference between symptoms of AFB and other brood diseases in the hive. We tell you the best methods for inspecting your hives.

The Law

New Zealand beekeepers have a number of legal obligations that must be met regarding AFB disease. Read the shortened list in summary, here.

Elimination

Most hives become infected because bees, honey or equipment have been put into a hive from another hive that is infected with AFB. Lower your chances of an AFB infection by reading this section.

AFB Recognition Course Info

Find out when the next AFB Recognition and Competency Courses, or Refresher Courses are available. These are held throughout the year in various New Zealand locations across the South Island and North Island.

The AFB App

Follow the link below to open the App. Once open to save to your device you need to bookmark the URL on your phone so you can find it easily again. Please click here to open.